|

| PCT5 Color Printer/Applicator |

|

| PCT5 Color Printer/Applicator In Action |

|

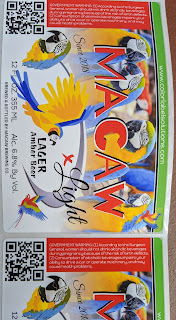

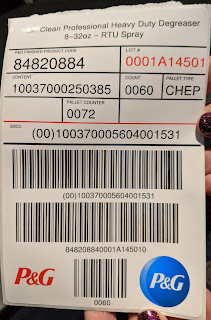

| Color Printed Label With Variable Data |

|

| PCT5 Color Printer/Applicator |

|

| PCT5 Color Printer/Applicator In Action |

|

| Color Printed Label With Variable Data |

|

| John Roberts with the Smart Touch Panel/C6000P |

|

| Smart Touch Panel |

https://colorlabelsondemand.blogspot.com/2020/02/my-new-c6500p.html

https://colorlabelsondemand.blogspot.com/2019/09/new-c6000-series.html

|

| C6500P In The Box |

After opening the box and removing the printer, I started the printer without ink and attempted to install the driver (Get the driver here); but the driver would not install. I realized quickly the install had to be done from the LED front screen and not the driver. The initialization took about 20 minutes (longer than the C3500). After the initiation process finished, I could install the driver; and learned the initiation process consumed about 50% of the initial ink cartridges (similar to the C3500).

|

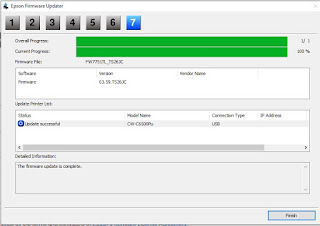

| C6500 Firmware Update |

Now that the driver was installed and the firmware updated, I decided to print some matte paper labels. I found loading the paper using the spindles very easy to do. (Note to self: we need to order more spindles). If you have ever used a LX2000, you’ll find the process with the C6500 much easier to do. (see my previous post comparing the LX2000 to the C7500. Check out the paper loading section):

|

| C6500 Media Spindle |

|

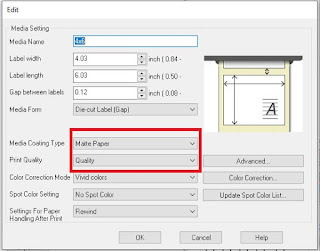

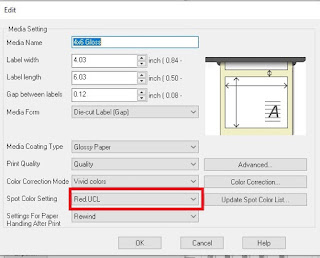

| C6500 Media Settings |

|

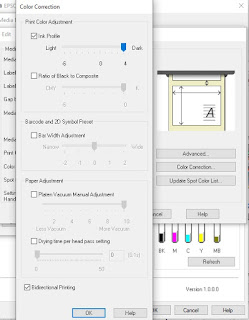

| C6500 Ink Profile |

|

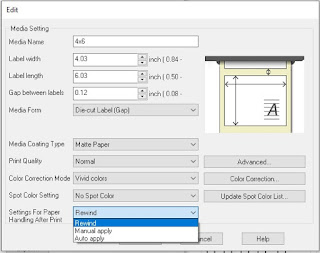

| C6500 After Print Settings |

|

| C6500 Matte Paper Labels |

|

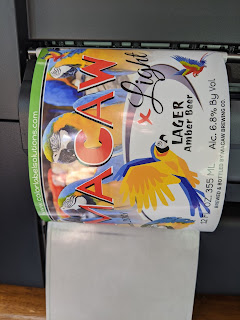

| C6500 Gloss Paper Labels |

Max Quality on the Gloss Paper is the maximum print resolution and slowest print. Watch these two labels print here:

|

| C6500P Peel & Present Feature |

|

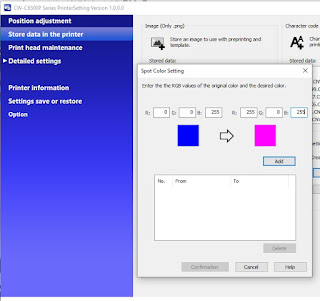

| C6500 Spot Color Setting |

|

| C6500 Spot Color Driver Setting |

|

| C6500 Spot Color Replacement; Check out the Blue Differences |

|

| C6500 Rear Feed of Large Labels |

|

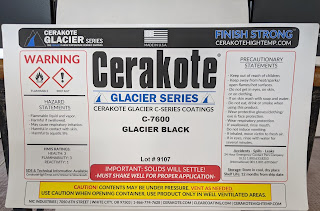

| C6500P Print Quality on Drum Labels |

|

| C6500P Peel & Present-Large Drum Labels |

This long label did stick to the liner below; but came loose when pulled. The Peel & Present feature would seem perfect for chemical drum labeling. I suggest owners of C831 printers upgrade ASAP.

Overall, my out-of-the-box experience with the C6500P was very positive. High Print Quality, Easy Operation, Unique Features like Peel & Present, Spot Color Replacement and Multiple Door Openings make the C6500 a great alternative to printers from Primera such as LX2000, LX900 or LX1000; from VIP such as the VP485 and VP495; or from Neuralabel, the 300x. If you have one of these printers, you should consider upgrading. And I did not test several the new features; MAC driver, Remote Printer Management or I/O port. We’ll get these tests done in the new future. Be sure to see my post on printing with ZPL here:

|

| ZPL Printed With The C6000A |

|

| Zebra Printers Use ZPL |

|

| Epson C6500P |

According to Bill, “Epson’s Escape Label is very similar to ZPL, but provides additional commands to add color to the ZPL. And the additional code required to add color is very small.” For example, Bill added a PNG image to the image itself to print the logo in the video; and he did not have to load the code into the printer itself. Some time ago, I discussed uploading an image to the C7500 and running ZPL:

https://colorlabelsondemand.blogspot.com/2018/05/zpl-with-c7500.html

|

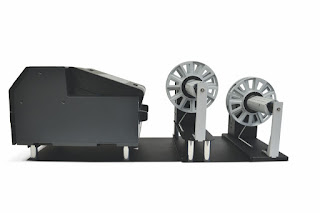

| C6000 Winders |

|

| C6000 Unwinder |

|

| C6000 Rewinder |

|

| C6500P |

|

| CTM Wrap Label Applicator |

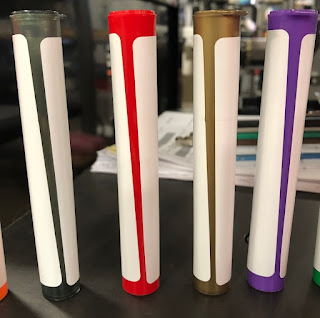

| Auto Applied Labels on CoolJarz 116 mm Tubes |

|

| Rectangle Labels on Tapered Tubes |

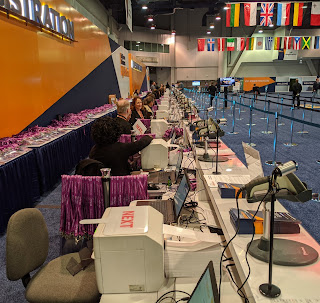

MJBIZCON2019 was a big success for Color Label Solutions, as we spoke with hundreds of customers and prospects during the event.

|

| MJBIZCON 2019 Booth |

|

| QL-300 |

|

| QL-300 Printed Silver Foil |

|

| QL-300 Printed Black Paper |

|

| C6500P |

|

| 4×6″ Gloss Poly Label Printed with the C6000 |

Place your order for the C6500A (8.375” wideprinter with cutter) printer here:

|

| C3500 Printers at MJBIZCON Registration Desk |

And our gloss paper tags printed great on the reliable, C3500 printers:

|

| C3500 Gloss Paper Badge |

|

| C7500 $1,000 Rebate |

Personalize your design down to the smallest detail. Once you have created a label template, you can start printing and applying labels to your products.

The Printer, The Applicator and your first 20,000 labels printed under $20K.

Label Machine Specifications:

Series: LabelOn Benchtop

Benchtop

Model: Round Products

Labeling accuracy: ±1/16th inch

Typical Labeling speed: 5 to 20 Pieces / min

Product Height: 1.0 inch to 12.0 inch

Product Diameter: ¼ inch to 6.5 inch

Label Length: ½ inch to 12.0 inch

Label Web Height: ½ inch to 5.0 inch

Label Roll Core: ID Φ 3 inch

Label Roll Diameter: OD Φ up to 12 inch

Label Machine Dimensions:

(L × W × H) 30 inch×16 inch×17 inch

Power supply: 110V 50/60HZ

Total Power: 200W (Approximately)

Air Pressure (PSI): 40+ PSI

Label Machine Specifications:

Series: LabelOn Benchtop

Benchtop

Model: Flat and Near Flat

Labeling accuracy: ±1/16th inch

Typical Labeling speed: 5 to 20 Pieces / min

Product Height: 1.0 inch to 7.5 inch

Product Width: 1.0 inch to 7.5 inch

Product Thickness: 0.1 inch to 7.5 inch

Label Length: ½ inch to 5.0 inch

Label Web Height: ½ inch to 5.0 inch

Label Roll Core: ID Φ 3 inch

Label Roll Diameter: OD Φ up to 12 inch

Label Machine Dimensions:

(L × W × H) 28 inch×15¼ inch×14 inch

Power supply: 110V 50/60HZ

Total Power: 200W (Approximately)

Air Pressure (PSI): 40+ PSI

Loop Benchtop Solution Series:

Loop Benchtop Solution Series:Epson’s most advanced print head technology “PrecisionCore linehead “

– Max. 300 mm/s high speed printing

– 600(H) dpi High print resolution

– Fine text. Bar-code printing

– Clear gradation printing

– High reliability with Nozzle Verification Technology

Command control which enable to minimize system re-design

– ZPL emulation

– ESC/Label command language

– On board template manager

Designed for industrial use

Continuous printing

– 8inch diameter roll paper

– Big volume Ink cartridge

– Original winder/re-winder(option)

High durability

– Long life(MCBF)

– Metal case

– Pigment ink

Expandability

– input/output external connection port (I/O port)

You can have your Printer, your Applicator and your first 20,000 labels printed for under $20K

Can be widely used in various vertical round bottles. Suitable for small production.

Optional Accessories:

Label applicator:

Apply label:

Control System:

Wrap station:

Conveyor and frame:

If your labeling tasks are now reaching 500 products a week or more, then you will appreciate how much time you will save with this and how much more consistent your product can look when you apply your labels with a semi automatic process.

Suitable for projects and labeling tasks where you have in excess of 500 products a week. This is a simple, cost effective mechanism to get your processes in line with being able to supply the small, the medium, and gearing up for the big guys.

The LabelOn range extends beyond this semi-automated LabelOn

range extends beyond this semi-automated LabelOn Benchtop Range.

Benchtop Range.

The next step from this range would be the LabelOn Mini where you have a small footprint inline machine with its own conveyor. This range is small to medium volume labeling capacity.

Mini where you have a small footprint inline machine with its own conveyor. This range is small to medium volume labeling capacity.

Following the Mini Range is the LabelOn Basic range where you have a medium footprint, higher capacity dedicated product range capability with medium to high volume labeling capacity.

Basic range where you have a medium footprint, higher capacity dedicated product range capability with medium to high volume labeling capacity.

The step beyond the LabelOn Basic range is the LabelOn

Basic range is the LabelOn Modular or Contractor range. This is a full sized inline machine with unparalleled versatility and configured for the most efficient and intuitive product changes possible.

Modular or Contractor range. This is a full sized inline machine with unparalleled versatility and configured for the most efficient and intuitive product changes possible.

Series: LabelOn Benchtop

Benchtop

Model: Flat and Near Flat

Labeling accuracy: ±1.0mm (±1/16th inch)

Typical Labeling speed: 8 to 30 Pieces / min

Product Height: 25mm to 190mm (1.0 inch to 7.5 inch)

Product Width: 25mm to 190mm (1.0 inch to 7.5 inch)

Product Thickness: 2.54mm to 190mm (0.1 inch to 7.5 inch)

Label Length: 12.7mm to 127mm (½ inch to 5.0 inch )

Label Height: 12.7mm to 127mm (½ inch to 5.0 inch)

Label Roll Core: ID Φ76 mm (ID Φ 3 inch)

Label Roll Diameter: OD Φ304mm (OD Φ up to 12 inch)

Machine Dimensions (L × W × H) 711mm×387mm×355mm (28 inch×15¼ inch×14 inch)

Power supply: 110/220V 50/60HZ

Total Power: 200W

Air Pressure (PSI): 40+ PSI

Check out our new LabelOn Mini Synergy Range:

Mini Synergy Range:

These are Power House pieces of labeling equipment that can sit on a workbench top and get through serious  production.

production.

See a video of the LabelOn Mini Synergy – Top Labeler in action hitting the mark Five times – one on top of the other! before we show its true function of providing tamper evident labeling.

Mini Synergy – Top Labeler in action hitting the mark Five times – one on top of the other! before we show its true function of providing tamper evident labeling.

The LabelOn Mini “Synergy” Range is a significant step up from semi-automated labeling and a great first step towards a production line.

Mini “Synergy” Range is a significant step up from semi-automated labeling and a great first step towards a production line.

This truly is the “Mini” of Labeling machines. Everything you would find in a larger machine and outgunning all competitor’s in this small footprint label machine arena as well as MANY larger footprint machines.

Compared to our Standard LabelOn Mini Range Enhanced features include:

Mini Range Enhanced features include:

IF you move forward with a LabelOn Mini Synergy you won’t look back as your operators will become familiar with mechanics and controls that are very similar to our full size production machines.

Mini Synergy you won’t look back as your operators will become familiar with mechanics and controls that are very similar to our full size production machines.

Chat with us at www.adeneli.com or call us toll free at 844-ADENELI (844-233-6354)

Purchasing used labeling machinery, sealing, and packaging machinery will definitely provide a path to lower machinery purchase costs- and it will feel like a great deal. But watch out- you could be setting yourself up for huge costs that far outweigh any savings you thought you might make by purchasing second-hand.

There are many ‘unseen’ costs of purchasing used label application machines, sealing machines and other packaging machinery. This is especially the case with Labeling machines.

Consider Employee Skill Set Requirements

Consider Employee Skill Set RequirementsThe skills required to operate older labelling* machines will far outway the skills to operate modern good value labeling equipment. Increased skill set employees means, increased training and dependence on higher paid more experienced staff to keep an old machine running (if you can find such staff – or keep them). Newer labeling machinery provides ease of use technology such as touch screen controls, motor speed synchronization and far more simple job changeovers; put simply new labeling equipment is usually far easier to operate. Setting up an old/used machine and teaching employees to properly use it can quickly eat into the “savings” you made buying the machine.

Reliability is a big factor. Although a machine may look like it is in good shape from the outside, used equipment is subject to previous wear and tear including items that might not be immediately visible. Even with a thorough manual inspection from a skilled technician, there are internal problems that can be missed. To name a few of the very likely things you will inherit; consider bent shafts, worn down gears and teeth, electronics on its last legs, obsolete operating systems and electronics and mechanical parts no longer produced.

The Big One: Loss of production TIME.

When production stalls your reputation, your profits and your business opportunities can all be significantly impacted.

Lengthy job set up times are NOT GOOD things; even if you have the advanced skill set employees to do them now. Compared to new labeling machines, most old machines have significantly longer and more complex set-up procedures.

now. Compared to new labeling machines, most old machines have significantly longer and more complex set-up procedures.

Would you buy a car you could not service for all the likely AND unlikely service events? New and old machines alike come with the responsibility of maintenance. Maintenance of old equipment is a much more tricky affair that often involves long waits for replacement parts ; if you can find them or if they still exist. You may want to back yourself that you are qualified to self service an old labeler, however, labeling machines have a simple task that is achieved with literally thousands of parts. Even experienced label machine representatives and engineers call upon their teams to solve some issues – with your old labeling machine you are a team of one with a fraction of the labeling knowhow of a company that designs and supplies the current labeling machinery.

Good new labelling* equipment can be serviced quickly if a problem arises. “Current” parts are much faster and easier to identify, reorder and install.

Consider the enhanced position you are in if you were to order a good value LabelOn labeling machine with its online gallery support. Communicating any service issue is instant, recorded for future reference and identified using pictures and video of current machinery and parts (see below).

labeling machine with its online gallery support. Communicating any service issue is instant, recorded for future reference and identified using pictures and video of current machinery and parts (see below).

Gallery Asset

Gallery AssetOlder labeling equipment may initially have a lower bottom line, but could really cost you in the long run. Current  labeling machinery allows for ease of use, quicker training, assured service and support plus significantly fast job turn around.

labeling machinery allows for ease of use, quicker training, assured service and support plus significantly fast job turn around.

Buying your labelling* machine, induction sealing machine and other packaging machinery can be a big decision, for your production process, its dependability and your pocketbook.

You really need to find great machinery; where you know it will work without breaking the bank or compromising the integrity of your production.

We provide the options that fit your needs and your budget- you won’t be overspending here. We can provide consulting and testing before you purchase your label applicators, induction sealers, or other packaging machinery. We are confident that in most cases we present the best value production solution.

If you are looking for affordable and trustworthy Labelling, Sealing, and packaging machinery, visit Adeneli Packaging websites and talk to one of our machine specialists,

Give us a call at (844)-233-6354 (844-ADENELI) or click the direct chat link below!

http://adenelipackaging.com – https://label-on.com/ – https://sealeron.com – https://capliningmaterial.com

*Labeling vs Labelling: We understand that you may see ‘labeling machines’ and ‘labelling machines’ within our web content. These are synonymous- just spelled differently in different regions of the world. We want our posts to be available to our world-wide audience, so we freely interchange the spelling to encourage easy searching for our content. Please rest assured, we are doing this on purpose!

If you have requirements of 1000 pcs a week or more, the LabelOn Bechtop Flat and Oval 1 or 2 labels machine will pay for itself extremely quickly. It will also make your shelf presence look like you were using accurate packaging equipment 4 or 5 times more expensive than this unit.

Bechtop Flat and Oval 1 or 2 labels machine will pay for itself extremely quickly. It will also make your shelf presence look like you were using accurate packaging equipment 4 or 5 times more expensive than this unit.

We can even configure this machine (at point of manufacture) so that it achieves an astonishing feat – a single full wrap of an oval product!!

Benchtop

Benchtop

For products that are unstable, we have a solution where you can use your LabelOn Mini machine and we can arrange for a set of pucks that you can easily load and unload to achieve the accurate labeling you need.

Mini machine and we can arrange for a set of pucks that you can easily load and unload to achieve the accurate labeling you need.

In this video, we are using the one puck, but when we supply you there would be 50+ pucks supplied.

In this video, we label a tall thin round bottle. Pucks can also be used for labeling products that are not round. For example, if you have an oval sided container that you want to wrap a label around, the puck would have a flat on one side; so a guide rail can “square the product” before it passes the label peel point, and enters between the wrap belt and the wrap backing plate.

Mini Synergy

Mini SynergyThe LabelOn Mini Synergy 510 – WRAP Labeling is Continuous.

Mini Synergy 510 – WRAP Labeling is Continuous.

The bottle enters between a Wrap Belt and a backing plate.

The Mini Synergy matches the speed of the label, and the wrap belt.

The LabelOn Mini “Synergy” Range is a significant step up from semi-automated labeling and a great first step toward a production line.

Mini “Synergy” Range is a significant step up from semi-automated labeling and a great first step toward a production line.

This truly is the “Mini” of Labeling machines. Everything you would find in a larger machine and outgunning all competitors in this small footprint label machine arena as well as MANY larger footprint machines.

Mini Range Enhanced features include:

Mini Range Enhanced features include:If you move forward with a LabelOn Mini Synergy, you won’t look back as your operators will become familiar with mechanics and controls that are very similar to our full size production machines.

Mini Synergy, you won’t look back as your operators will become familiar with mechanics and controls that are very similar to our full size production machines.

The LabelOn

Mini Synergy Range

Its Much more than a Mini Labeling Machine

At LabelOn , we have listened to the market very carefully. Small Labeling Machines need to operate like our larger labelling machines.

, we have listened to the market very carefully. Small Labeling Machines need to operate like our larger labelling machines.

The Mini Labeling machines need to get out a good level of production volume, accurately and (importantly) with the ease of set up found on our bigger LabelOn Basic labeling machines.

Basic labeling machines.

Our Small Labeling Machines have Touch panel controls and Synchronized Motor Speeds. When you have Mini Labeling Machines with the features we have packed into our Bottle Labeling Machines, you have Labeling Machines that require a much lower operator skill set than the skill set required to operate Small Labeling Machines that fail to include the features of the LabelOn Mini Synergy Range of Small Labeling Machines.

Mini Synergy Range of Small Labeling Machines.

If you are looking for affordable and trustworthy Labelling, Sealing, and packaging machinery, visit Adeneli Packaging websites and talk to one of our machine specialists,

Give us a call at (844)-233-6354 (844-ADENELI) or click the direct chat link below!

http://adenelipackaging.com – https://label-on.com/ – https://sealeron.com – https://capliningmaterial.com

*Labeling vs Labelling: We understand that you may see ‘labeling machines’ and ‘labelling machines’ within our web content. These are synonymous- just spelled differently in different regions of the world. We want our posts to be available to our world-wide audience, so we freely interchange the spelling to encourage easy searching for our content. Please rest assured, we are doing this on purpose!

I’ve written about Chris and Delta9 Systems in the past.

According to Ashley Crosh, Marketing Manager for General Data and producer of this podcast, “our goal of this podcast series is to gain credibility and visibility within the cannabis industry. We’re combining our expertise in data management and barcode systems with Chris’s in-depth understanding of the cannabis business to elevate producers, processors and retailers to a higher level.”

This post features ideas on how to improve print quality

Why is variable data so important in cannabis?

This post from some time ago reviews the California label requirements for cannabis products

The Boxmate comes in two sizes. First the Boxmate 610 for boxes up to 6” wide, costs $3,500:

|

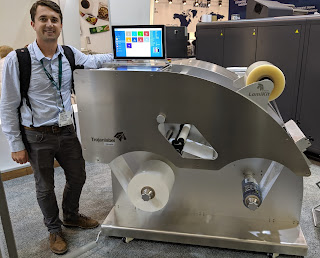

| Guy Mikel at Label Expo |

|

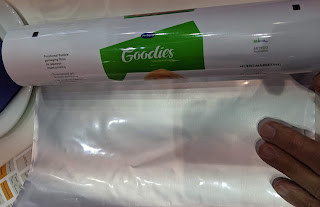

| Foil-Lined, On-Demand Color Flexible Packaging |

|

| Vertical Filling/Sealing Flexible Packaging Equipment |

|

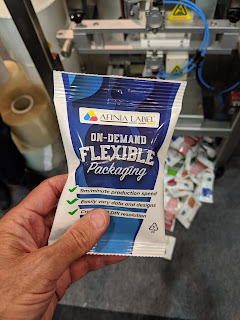

| On-Demand Color Flexible Packaging |

|

| L901 with Lamination Station |

|

| T2-L with Lamination Station |

|

| T2-C I/O Interface |

|

| Primera LX610 Print/Die-Cut |

|

| X610 Print/Die Cut |

|

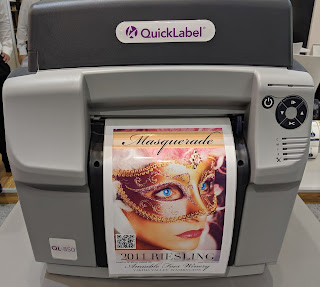

| QL-850 With Natura Ink |

|

| Inkjet Coated Tyvek |

|

| Behind the Glass Labeling |

|

| NS Multi Deionizer Unit |

|

| NS Multi Vacuum Pump |