On Monday September 23rd, 2019 in Las Vegas at Pack Expo:

|

| Epson C6000 Launch at Pack Expo |

and Tuesday September 24th, 2019 in Brussels at Label Expo Europe:

|

| Epson C6000 Launch at Label Expo Europe: |

Epson launched a new series of 4, on-demand color label printers to their ColorWorks lineup; The C6000A (4” version with Automated Cutter), C6000P (4” version with Peel/Present), C6500A (8” version with Automated Cutter), and C6500P (8” version with Peel/Present). Read the Epson press release here:

Epson Press Release:

https://news.epson.com/news/colorworks-c6000-series-color-label-printers

Learn more here on the Color Label Solutions page:

https://colorlabelsolutions.com/epson-c6000-and-c6500-color-inkjet-label-printers/

Epson page:

According to Epson, the C6000 series are the first color label printers designed to replace black-only thermal transfer printers. Epson American has dubbed them, “The Tough Guys”.

|

| Epson C6500P |

Having worked with these printers briefly, I see the following capabilities that make the C6000 series great new additions to the on-demand color labeling world.

First, the C6000 series offers up to 1200 x 1200 dpi resolution; providing high resolution, print output comparable to preprinted labels. Higher print quality has been one of the missing elements from earlier printers, especially in the wider print widths.

Second, Epson has decided to offer the C6000 series at a very affordable price; under $4,000. From $2,580 for the C6000A to $3,980 for the C6500P. With an 8” wide version at this price, we see a real fit with many of our customers.

Third, the C6000P and C6500P come with a Peel and Present capability, making labeling easier to do for operators. Now, operators can send a large batch print job; and then pull each label from the printer already peeled. No other color label printer offers this capability. Watch the Peel/Present function here:

Fourth, the C6000 offers Remote Printer Management, enabling organizations to manage fleets of printers. Checking consumable status, updating firmware, confirming errors, etc. is possible from a central location using the C6000 series of printers. No other color label printer offers this capability.

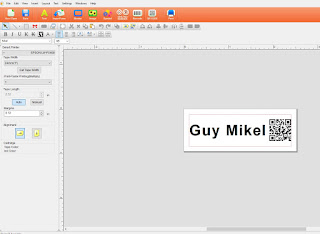

Fifth, the C6000 enables integration with ZPL (Zebra Print Language). This capability enables organizations to use the C6000 as a “Plug & Play” option for applications normally reserved for thermal transfer printers. Users can upload images that would normally be preprinted; and then send the same ZPL to print colorized labels on demand. Learn more about how I did this process using the C7500:

Further, the C6000 series integrates with SAP “out-of-the-box”.

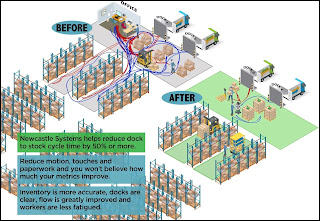

Sixth, the C6000 offers I/O capabilities to enable integration into automated workflows. Now, automated label applicators can be built to integrate these color label printers; especially with the “First Out”, Peel and Present capability in the C6000P and C6500P. No other color label printers offer this combined capability.

Together, the third, fourth, fifth and sixth capability discussed here make the C6000 series a good option for thermal transfer printers; especially thermal transfer users with a large number of preprinted labels in inventory. These customers can print labels on-demand versus keeping them in inventory. According to Victor Gomez, Group Product Manager for Color Labels at Epson, “the ink costs of printing labels with the C6000 are less than or only slightly more than using a thermal transfer ribbon; especially after the increase in resin prices.”

According to Andy Scherz, senior product manager, Commercial Label Printers, Epson America, Inc. “The new family of ColorWorks on-demand label printers provides an easy transition for customers looking to make the switch from black-only, thermal transfer printers, with similar media handling capabilities, speed, features, and connectivity options.” With the launch of the C6000 series, thermal transfer users should consider moving to these new, on-demand color label printers.

Seventh, the C6000 printers now come with both MAC and Linux print drivers. Over the past several years, a MAC driver has been a very frequent request. Many graphic designers use MAC’s; and now they can print labels directly from their MAC Books.

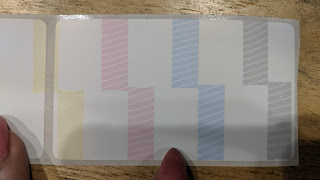

Eighth, the C6000 offer “Spot Color Replacement” option. Now in the C6000 driver, operators can easily change the RGB color without changing the original artwork. Further, advance users will be able to upload ICC Color Profiles. ICC Color Profile is a set of data that characterizes a color input or output device, or a color space, according to standards promulgated by the International Color Consortium (ICC).

No other desktop or benchtop color label printers offers this capability.

Ninth, the C6000 series comes with the same durability and reliability seen with both the C3500 and C7500 printers. Further, Epson service offers both Spare in the Air (SITA) and On-Site warranty; making these printers easier to use and to keep running.

|

| LX2000 Color Label Printer |

Combining the points one, seven, eight and nine make the C6000 series a great alternative to the LX900, LX910, LX1000, and the LX2000 from Primera. In the past, Primera printer’s higher print quality has made them a good option; even with their higher ink costs. Read my earlier comparison of the C7500 to the LX2000 here: https://colorlabelsondemand.blogspot.com/2017/09/lx2000-vs-c7500.html

|

| LX900 Color Label Printer |

Also, ink costs for the new C6000 printers are lower than Primera printers. According to Jacob Kalleris, Product Manager for Epson Europe, “Current Primera customers will save a significant amount of money for ink by moving to the new C6000 printers.”

In addition to alternatives to thermal transfer and Primera printers, the C6000 series printers offer users of other label printers a good option. The most obvious replacement target for the C6000 are users of the C831 printer.

|

| C831 Color Label Printer |

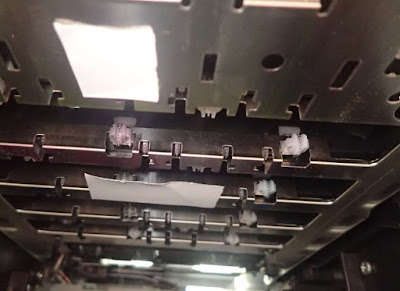

The C831 has performed well for chemical manufacturers to produce GHS labels. Now the new C6500 (P or A depending on the requirement for peel and present), makes printing GHS easier to do (i.e. clearing any potential jams) and produces higher resolution print quality. Plus, users will save money on their labels as the C6500 doesn’t require pin-feed media. Moving to the C6500 from the C831 should be an easy decision for most users.

|

| C3500 Color Label Printer |

Besides the C831, certain users of the C3500 should consider upgrading to the C6000P. The C6000P will offer higher print quality, peel & present and Fleet Management capability. With these three advantages, many C3500 printer users should upgrade to the C6000.

Overall, the new C6000 and C6500 label printers offer users several very key benefits. If you currently use the C831 printer, a C3500 printer, one of the Primera desktop printers (LX900, LX910, LX1000, and the LX2000) or a thermal transfer printer who wants to colorize their print output, consider upgrading to one of the new C6000 printers. Epson says we can begin shipping the C6000 printers by January. Watch our store for when we start taking orders for the C6000 printers:

Shortly, we will receive a demo C6000 printer; therefore, look for more testing commentary from us.

If you are interested in learning more about the C6000 printer for your operation, contact us. We look forward to working with you to see how these exciting new color label printers fit your operation.

Guy Mikel

855-962-7670

Mini machine

Mini machine