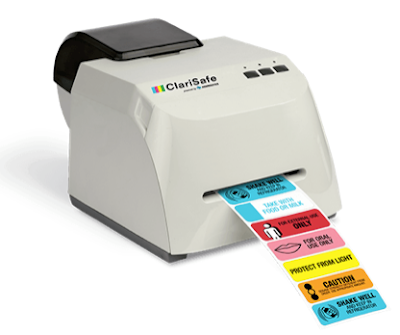

Recently, I attended a presentation by Mike Corcoran on designing label artwork for the QL-300. As a Graphic Designer with years of experience and extensive knowledge in the packaging industry, Mike was able to provide valuable insight into the printing capabilities of the QL-300, the world’s first 5-color toner-based tabletop printer. The QL-300 is a LED-based printer with the capability to add white to labels. Additionally, the QL-300 enables the use of many new types of materials for print-on-demand color labels.

|

| QL-300 |

You may remember the first post on the QL-300:

https://colorlabelsondemand.blogspot.com/2019/02/ql-300-white-new-materials.html

After listening to Mike, I’m convinced the QL-300 offers ample opportunities for companies to create unique looks and effects with on-demand color label printing. Let me give you an overview of why and how to use white and a wide variety of unique materials to create exciting, beautiful label designs.

First, why white? According to Mike, “White can stand on its own, but can also lay behind colored elements to prevent them from blending into dark media or dark elements behind clear media.”

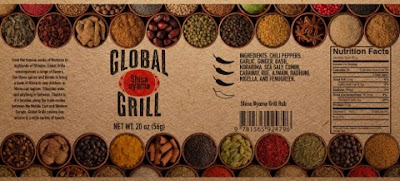

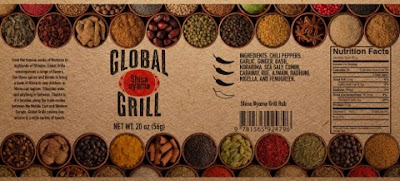

To illustrate this point, Mike created this example label artwork for Kraft paper.

|

| Kraft Label With No White |

Notice two different aspects of the label print output. First, the barcode would probably not scan with the Kraft background. For all retail products, it’s imperative that the barcodes scan at checkout or retailers will issue a fine. Also, notice how the nutritional facts are somewhat difficult to read with the Kraft background.

Second, notice how some of the colors of the various spices have blended into the background of Kraft paper. When branding requires materials such as Kraft, you may want the color to “pop” more.

By adding white as a background, you can ensure barcodes scan well and text is easy to read. Further, you can make the color stand out on dark backgrounds by adding white behind the colors.

|

| QL-300 Printed Kraft With White |

This print output on Kraft paper looks noticeably better using the white background.

In addition to Kraft, white can a add pop on clear film as well as enable you to use the color elements of the actual product as a part of your artwork. In this image, Mike shows how clear film uses the color of the product as a design element.

|

| White Vs Clear (With White Printed) Label |

|

| White On Clear Featuring The Product |

In this design, Mike used the white to highlight the label design as well as the background to ensure the colors stand out.

In addition to materials such as Kraft and clear film, the QL-300 enables other materials to create interesting effects.

|

| QL-300 Printed Materials |

In this image, Mike shows how black toner on black paper creates almost a gloss or UV coating effect. Black toner on a black label would seem to be an interesting effect; a designer’s dream! However, you would not use white behind black ever.

To create stunning, beautiful artwork to take advance of the QL-300, Mike recommends Adobe Illustrator. (Please know: I’m not an A.I. expert). AI enables a graphic artist to design in images, add backgrounds and covert fonts to outlines.

Once the artwork has been created, Mike made one additional key point: save the files as a PDFX/x_1a:2001. PDF/X is a subset of the PDF ISO standard. The purpose of PDF/X is to facilitate graphics exchange, and therefore, has a series of printing related requirements which do not apply to standard PDF files. To learn more about this standard;

https://en.wikipedia.org/wiki/PDF/X

To learn more about design for the use of white and interesting label materials, check out this video from Mike:

https://www.youtube.com/watch?v=NpPqSYPkArA&feature=youtu.be

From my perspective, I see the QL-300 fitting three types of customers. First, cannabis companies should consider the QL-300 where branding includes the use of foils, as well as many other design elements. Second, food manufacturers, where clear film that enables the use of the product/product color as a part of the brand/label artwork. Third, commercial printers who want to offer these capabilities to their customers.

|

| QL-300 Print Samples |

For commercial printers, it’s worth noting that the QL-300 enables the use of ICC profiles and will soon offer a Postscript driver and RIP software (Raster Image Processor). Many commercial printers may prefer this functionality as a part of their label printing workflow.

My thanks to Mike Corcoran for a great presentation and important education. As Mike says, “the QL-300 is a game changer in print-on-demand color label printing.” And our Graphic Artist, Tony Molina, says “having the white option gives label designers tremendous creative possibilities as well as flexibility when creating color labels. The option to use white as a design element will make your artwork unique.”

If you want to create and print unique label artwork, contact us. We’ll help you get starting printing with the new QL-300.

Guy Mikel

855-962-7670

Purchase the QL-300 here: