Comparing Plastic or Glass Containers 1. Product Handling With Glass you need to be more careful with product handling as glass breaks. Extra precautions include insuring there are no places where a build-up of product would result in an overflow of product that would fall off the machine. Glass products can “catch” on one another and cause […]

Author Archives: admin

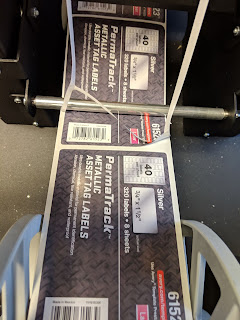

Product Labeling Samples Process -Advising and Proceeding with Confidence

Labeling Machine Inquiry or Order Process The following article going over the assessment of labels and bottles for a given Labeling Machine inquiry or order. With this level of knowledge applied to a client inquiry, you can confidently move forward with both machine and label supply. The consistency of products is entirely out of our […]

Labeling Machine Fault Finding

A key strength to our labeling machine supply is how we go about fault finding. For LabelOn™ when there is a problem, we treat it as an opportunity ; an opportunity for us to shine and show our clients how we pull clear from any other labeling equipment solution that is on offer. “it’s […]

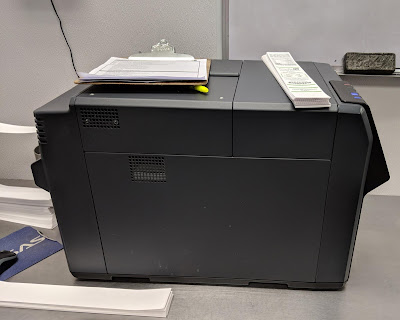

LabelOn™ and Epson Combine

An Industrial

Full Color Retail Label Printer

With An Industrial

Bench Top Label Applicator

You can now Print and Apply

Your Own Retail Quality Labels.

- You have control of your labels

- You make the label changes without waiting

- You can developing your range – Minimum label print runs will no longer stop you

- You can customize batches of labels

- You do not need to wait for labels to be printed and then shipped

Create Your Own Personalized Label Designs

Personalize your design down to the smallest detail. Once you have created a label template, you can start printing and applying labels to your products.

The Printer, The Applicator and your first 20,000 labels printed under $20K.

In Action

In Action

Label Machine Specifications:

Series: LabelOn Benchtop

Benchtop

Model: Round Products

Labeling accuracy: ±1/16th inch

Typical Labeling speed: 5 to 20 Pieces / min

Product Height: 1.0 inch to 12.0 inch

Product Diameter: ¼ inch to 6.5 inch

Label Length: ½ inch to 12.0 inch

Label Web Height: ½ inch to 5.0 inch

Label Roll Core: ID Φ 3 inch

Label Roll Diameter: OD Φ up to 12 inch

Label Machine Dimensions:

(L × W × H) 30 inch×16 inch×17 inch

Power supply: 110V 50/60HZ

Total Power: 200W (Approximately)

Air Pressure (PSI): 40+ PSI

Label Machine Specifications:

Series: LabelOn Benchtop

Benchtop

Model: Flat and Near Flat

Labeling accuracy: ±1/16th inch

Typical Labeling speed: 5 to 20 Pieces / min

Product Height: 1.0 inch to 7.5 inch

Product Width: 1.0 inch to 7.5 inch

Product Thickness: 0.1 inch to 7.5 inch

Label Length: ½ inch to 5.0 inch

Label Web Height: ½ inch to 5.0 inch

Label Roll Core: ID Φ 3 inch

Label Roll Diameter: OD Φ up to 12 inch

Label Machine Dimensions:

(L × W × H) 28 inch×15¼ inch×14 inch

Power supply: 110V 50/60HZ

Total Power: 200W (Approximately)

Air Pressure (PSI): 40+ PSI

It is a Real Value Proposition:

The Epson TMC7500/G Paired with our LabelOn Loop Benchtop Solution Series:

Loop Benchtop Solution Series:

Epson’s most advanced print head technology “PrecisionCore linehead “

– Max. 300 mm/s high speed printing

– 600(H) dpi High print resolution

– Fine text. Bar-code printing

– Clear gradation printing

– High reliability with Nozzle Verification Technology

Command control which enable to minimize system re-design

– ZPL emulation

– ESC/Label command language

– On board template manager

Designed for industrial use

Continuous printing

– 8inch diameter roll paper

– Big volume Ink cartridge

– Original winder/re-winder(option)

High durability

– Long life(MCBF)

– Metal case

– Pigment ink

Expandability

– input/output external connection port (I/O port)

You can have your Printer, your Applicator and your first 20,000 labels printed for under $20K

Take the Tour of the Industrial Color Label Printer

LabelOn™ Benchtop Flat and Near Flat Label Applicator

Flat and Near Flat Surface Labeling

If your labeling tasks are now reaching 500 products a week or more, then you will appreciate how much time you will save with this and how much more consistent your product can look when you apply your labels with a semi automatic process.

Suitable for projects and labeling tasks where you have in excess of 500 products a week. This is a simple, cost effective mechanism to get your processes in line with being able to supply the small, the medium, and gearing up for the big guys.

The LabelOn range extends beyond this semi-automated LabelOn

range extends beyond this semi-automated LabelOn Benchtop Range.

Benchtop Range.

The next step from this range would be the LabelOn Mini where you have a small footprint inline machine with its own conveyor. This range is small to medium volume labeling capacity.

Mini where you have a small footprint inline machine with its own conveyor. This range is small to medium volume labeling capacity.

Following the Mini Range is the LabelOn Basic range where you have a medium footprint, higher capacity dedicated product range capability with medium to high volume labeling capacity.

Basic range where you have a medium footprint, higher capacity dedicated product range capability with medium to high volume labeling capacity.

The step beyond the LabelOn Basic range is the LabelOn

Basic range is the LabelOn Modular or Contractor range. This is a full sized inline machine with unparalleled versatility and configured for the most efficient and intuitive product changes possible.

Modular or Contractor range. This is a full sized inline machine with unparalleled versatility and configured for the most efficient and intuitive product changes possible.

Series: LabelOn Benchtop

Benchtop

Model: Flat and Near Flat

Labeling accuracy: ±1.0mm (±1/16th inch)

Typical Labeling speed: 8 to 30 Pieces / min

Product Height: 25mm to 190mm (1.0 inch to 7.5 inch)

Product Width: 25mm to 190mm (1.0 inch to 7.5 inch)

Product Thickness: 2.54mm to 190mm (0.1 inch to 7.5 inch)

Label Length: 12.7mm to 127mm (½ inch to 5.0 inch )

Label Height: 12.7mm to 127mm (½ inch to 5.0 inch)

Label Roll Core: ID Φ76 mm (ID Φ 3 inch)

Label Roll Diameter: OD Φ304mm (OD Φ up to 12 inch)

Machine Dimensions (L × W × H) 711mm×387mm×355mm (28 inch×15¼ inch×14 inch)

Power supply: 110/220V 50/60HZ

Total Power: 200W

Air Pressure (PSI): 40+ PSI