FYI: I received my first C6500P printer.

|

| C6500P In The Box |

As I tested this exciting new technology, I thought you might find my out-of-the-box experience of interest. You might find my introductory post on the C6000 series printers of interest:

After opening the box and removing the printer, I started the printer without ink and attempted to install the driver (Get the driver here); but the driver would not install. I realized quickly the install had to be done from the LED front screen and not the driver. The initialization took about 20 minutes (longer than the C3500). After the initiation process finished, I could install the driver; and learned the initiation process consumed about 50% of the initial ink cartridges (similar to the C3500).

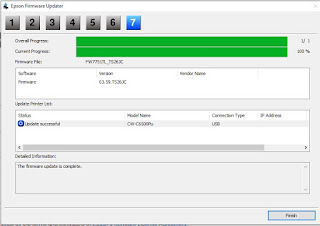

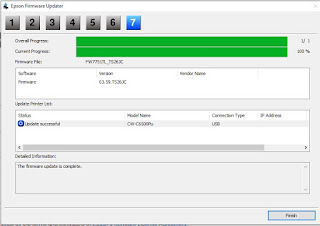

Once initialized, I checked the firmware version to see if it was up-to-date; it wasn’t. It is not surprising as these printers are brand new to the market. Epson has the updated firmware on the same site as the driver above. After downloading the firmware, I installed the updated firmware.

|

| C6500 Firmware Update |

I found the firmware update process very similar to my inexpensive, Multifunction, WF-4720, Epson printer.

Now that the driver was installed and the firmware updated, I decided to print some matte paper labels. I found loading the paper using the spindles very easy to do. (Note to self: we need to order more spindles). If you have ever used a LX2000, you’ll find the process with the C6500 much easier to do. (see my previous post comparing the LX2000 to the C7500. Check out the paper loading section):

|

| C6500 Media Spindle |

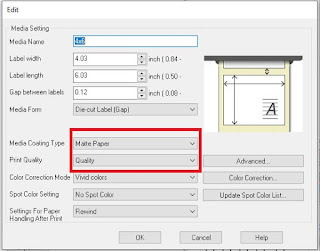

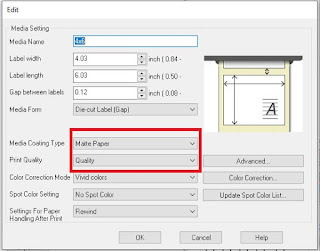

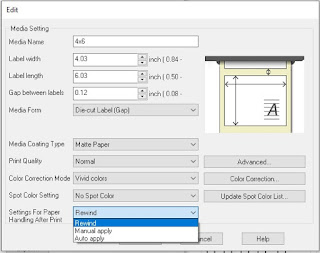

For the matte paper, I selected the normal quality setting;

|

| C6500 Media Settings |

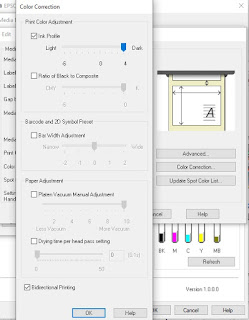

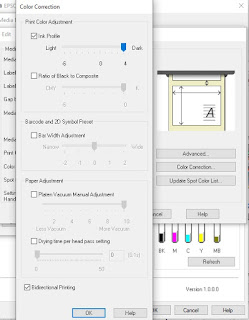

In addition, I changed the Ink Profile in the Advance setting to the darkest setting. I’d recommend this change on most all artwork and applications.

|

| C6500 Ink Profile |

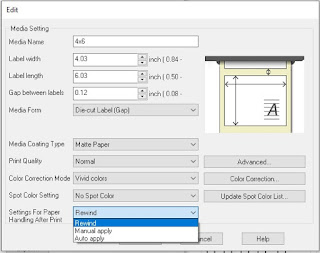

Finally, be sure to configure the settings to “Rewind” if you are not using the Peel & Present feature:

|

| C6500 After Print Settings |

Otherwise, the printer will tell you to remove the label. If you don’t change this configuration, the next label will not print. You can move the label slightly and the next label will print.

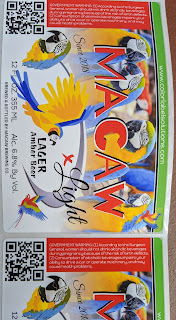

And found the print quality and speed (about the same as a LX2000) very good.

|

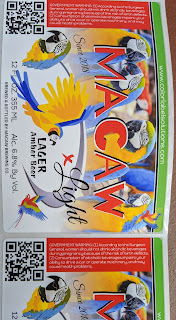

| C6500 Matte Paper Labels |

After my first print jobs, I loaded some gloss paper and printed both at the Quality and Max Quality. I did notice a slight difference in colors; but very little. Notice the differences in the green bar; and maybe the red block. Frankly, I don’t think that vast majority of users will use the Max Quality setting.

|

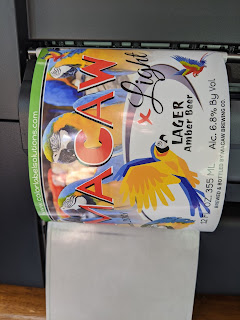

| C6500 Gloss Paper Labels |

Max Quality on the Gloss Paper is the maximum print resolution and slowest print. Watch these two labels print here:

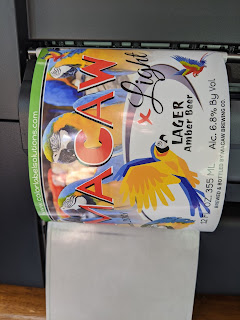

Now that I was printing labels, I tested the Peel & Present feature on the C6500P. I changed the configuration in the driver to “Manual Apply”; and loaded the liner through the peeler. The Peel & Present worked great!

|

| C6500P Peel & Present Feature |

No other color label printer offers this feature. If you have operators on the line printing and applying labels by hand, this feature will increase productivity. Please know: the Peel & Present version does not have a cutter.

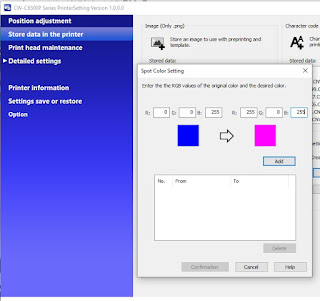

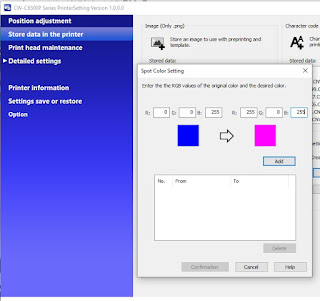

After using the Peel & Present feature, I tested the new Spot Color replacement capability in the Epson driver. With this capability, the printer can change one color automatically. In the Printer Setting Utility (Stored Data section), you establish an RGB value to replace an existing color.

|

| C6500 Spot Color Setting |

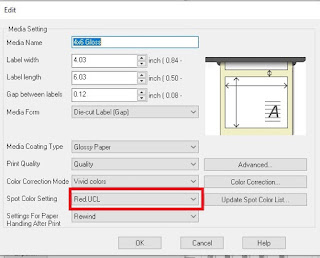

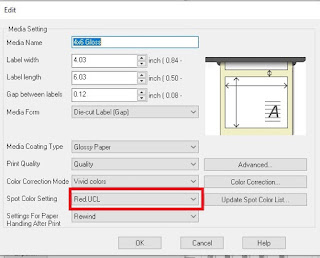

And then you select the color in the media definition section of the driver:

|

| C6500 Spot Color Driver Setting |

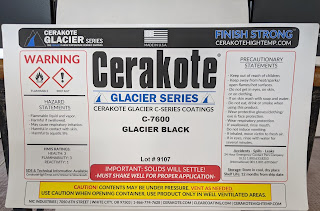

And you can change the print output colors without changing the artwork. See how the blue block below has a different color. Again, no other printer I know offers this capability.

|

| C6500 Spot Color Replacement; Check out the Blue Differences |

This feature seems to work only with artwork created as RGB, and not CYMK. More to come on the Spot Color Replacement.

After all these tests, I want to try rear feed using very large drum labels; 8.375” x 13.875”. Again, I see the C6500P as a perfect replacement for the C831 printer. With large labels and rear feed, opening the media cabinet from the back was very convenient.

|

| C6500 Rear Feed of Large Labels |

And using the Synthetic setting at the Normal Print Quality, I found the print speed faster than expected; probably faster than the C831. Watch me print this long label here:

And the print quality as well better than expected with the C831.

|

| C6500P Print Quality on Drum Labels |

After testing these large drum labels, I wondered how well the Peel & Present feature would work on 8.375” x 13.875” size. Peel & Present seemed to work well.

|

| C6500P Peel & Present-Large Drum Labels |

This long label did stick to the liner below; but came loose when pulled. The Peel & Present feature would seem perfect for chemical drum labeling. I suggest owners of C831 printers upgrade ASAP.

Overall, my out-of-the-box experience with the C6500P was very positive. High Print Quality, Easy Operation, Unique Features like Peel & Present, Spot Color Replacement and Multiple Door Openings make the C6500 a great alternative to printers from Primera such as LX2000, LX900 or LX1000; from VIP such as the VP485 and VP495; or from Neuralabel, the 300x. If you have one of these printers, you should consider upgrading. And I did not test several the new features; MAC driver, Remote Printer Management or I/O port. We’ll get these tests done in the new future. Be sure to see my post on printing with ZPL here:

Contact us if you find the features of the C6500A or C6500P of interest. We’ll make printing with these new technology printers easy to do.

Guy Mikel

855-962-7670

info@colorlabelsolutions.com