ColorLabel Solutions is the premier provider of print on-demand color label systems. But did you know we also manufacturer and sell thermal transfer and direct thermal labels as well?

|

| Black Rhino Labels |

Color Label Solutions became a manufacture of labels with the purchase of our company by General Data on March 1st 2019. Learn more here.

General Data (GDC) is one of the largest and most diversified manufacturers and converters of thermal transfer and direct thermal labels. Our expertise spans multiple industries and applications, including barcode labels for industrial applications, manufacturing, warehousing, logistics, packaging, food and beverage, cold storage, and healthcare. GDC produce labels that stand up to all sorts of harsh conditions, including abrasion, moisture, chemicals, solvents and temperature extremes. GDC produces both standard and custom size thermal labels, and we can supply you these labels.

Many (or maybe most) of our customers use either thermal transfer or direct thermal labels somewhere in their operation. But when should you use either technology?

Choosing Between A Thermal Transfer and Direct Thermal Print Solutions

In simplest terms, thermal transfer printing utilizes a thermal ribbon and direct thermal printing does not.

Thermal transfer involves the thermal printhead elements (dots) heating the backside of a thermal transfer ribbon to melt and transfer the compounds on the front side of the ribbon to the label material, thus creating the printed image.

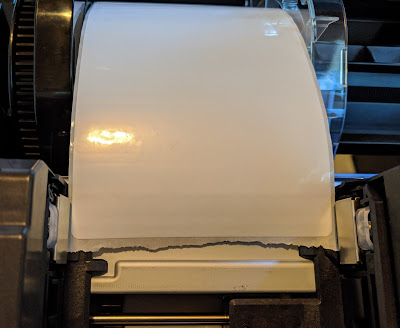

|

| Direct Thermal Printing |

Direct thermal printing requires a heat sensitive label material. The printhead elements come into direct contact with the heat sensitive material where the heat from the elements causes a color change in the material to create the printed image.

To learn more about the differences between direct thermal and thermal transfer printing, watch this GDC video:

Knowing the difference between thermal transfer printing and direct thermal printing is only the first step in evaluating the two alternative technologies for use in your label printing application. The following considerations, while not an exhaustive list, account for the key areas to review when selecting which technology to use.

- THERMAL PRINTHEAD LIFE & COST

- PRINTER CONFIGURATION & COST

- MEDIA SELECTION & COST

- LABEL LIFE REQUIREMENTS

Learn more about when to use either direct thermal or thermal transfer labels in this article from Sato Corporation:

Our team of print experts can help you identify the best printer and label for your specific application. Contact us today for more details.

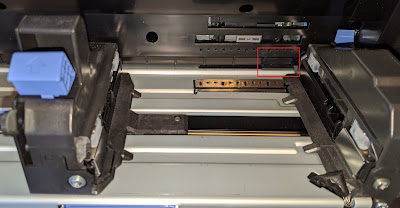

|

| Linerless Labels |

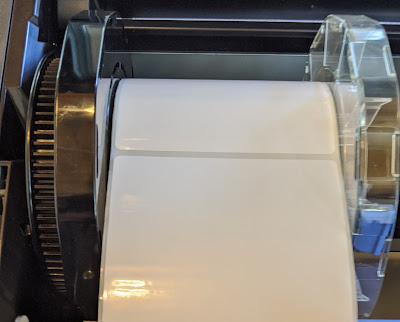

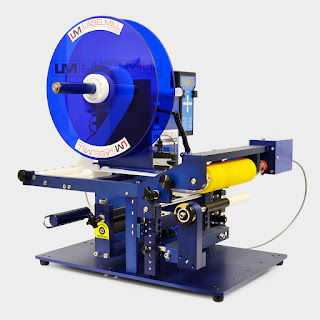

For direct thermal labels, GDC produces linerless labels. Linerless labels eliminate the need for liner, thus reducing waste and saving money. Learn more about linerless labels here:

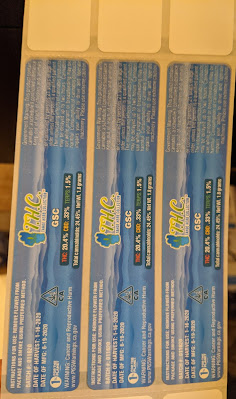

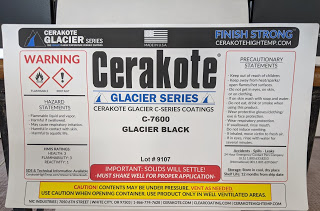

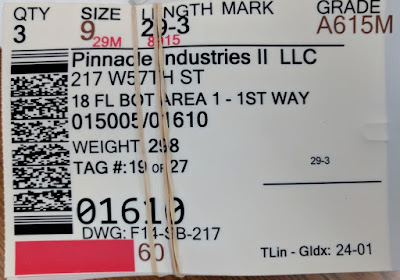

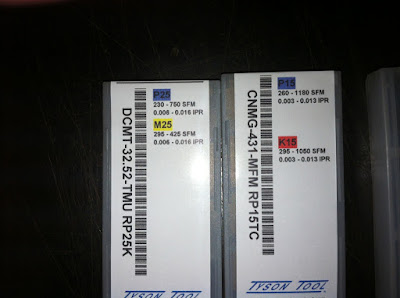

GDC proudly manufactures the Black Rhino™ brand of labels and tags. These high-quality barcode labels come in a wide variety of sizes and configurations, and are suitable for a number of different applications. Black Rhino provide outstanding performance and print quality in thermal labels, including printers from Zebra, Intermec, Honeywell, Sato, Datamax, and others. And we’ve got hundreds of SKU’s of Black Rhino brand labels in stock, ready for immediate shipment. If we don’t carry the label that you need in stock, we can make it for you. General Data’s custom thermal label manufacturing expertise is unparalleled in the industry.

|

| Grant Grooms |

When asked why to purchase thermal labels from GDC, Grant Grooms, National Sales Manager, says “Unlike other companies who purchase label stock to convert, GDC makes our own thermal materials. These components come from long-term partners, who provide us consistent raw materials. By working with GDC, you have a One-Stop-Shop/One Throat to Choke Business that provides consistent, high-quality thermal labels.”

If you use direct or thermal transfer labels, contact us. We can save you money and make your label purchasing easier to do.

Guy Mikel

855-962-7670